X-Line Automatic Coating Machine

A high speed in-line coating solution for applying EnduroShield, the industry’s best performing easy clean glass coating.

The X-Line fully automated machine combines uncomplicated design and smart technology to deliver a user friendly, high speed, efficient and economical coating solution for easy implementation. Designed and built by EnduroShield for customer driven functionality, the fully automated vertical or horizontal systems streamline the application of EnduroShield easy clean glass coating, allowing scalability to any size of operation.

- Fast and efficient

30 seconds per panel / average of 12 meters per minute - In-line or stand alone

Reduces double handling and does not impact production flow - Driving value

Economically priced with less waste - an affordable machine which applies the right amount of coating, every time - Complete flexibility

Horizontal or vertical, single sided or double sided coating machine options available.

Installed in-line at some of the world’s leading glass processing plants, reducing labour and product costs by up to 25%.

“As one of North America’s largest shower door manufacturers, we have partnered with EnduroShield since 2009. The migration to the new X-Line, being a single piece flow solution provides us the flexibility and efficiencies consistent with our focus for continuous growth.”

Jared Ross, Former President – HMI

Fully automatic edger, model TLR 11 AV C PC H85

Lattuada fully automatic 11-wheel mitering machine, equipped with:

- A-WR System: diamond and resin wheels automatic pre-setting plus polishing wheels automatic wear recovery

- i-AL package: a comprehensive pack of mechanical, electronic and software systems especially designed to deliver the maximum possible automation in glass processing and a full integration with the customer entire production system – this package allows an automatic adjustment of the machine’s parameters based on the glass thickness

- Motorized adjustable infeed conveyor

- Digital ammeters and automatic alert system for the polishing wheels wear

- Progressive lubrication system

- KDL: a special device equipped with two sensors mounted at the outlet to measure the exact length of each glass pane exiting the machine

- Incoming glass thickness control sensors

- Teleservice

FUX 83-LMP-37 Platenmelter for 5gal/20kg Pails

FUX Maschinenbau & Kunststofftechnik GmbH - the leading manufacturer of profile wrapping, lamination and profile bending equipment - is showing their new 83-LMP-37 5-gallon (20-kilogram) Platen / Pail Melter for PUR Hotmelt adhesive at GlassBuild 2022.

The main technology for adhesive dispersion that FUX promotes is their continuous tank system, or for smaller and more flexible runs, the Top Melter. Nevertheless as FUX already offers Platenmelters for the 55-gallon Barrels of adhesive they are now also launching their new 83-LMP-37 5-gallon (20-kilogram) Platen / Pail Melter due to popular demand of our customers in North America

As a company with a history of more than 475 years, FUX engineers reliable state-of-the art machinery and develops process solutions in conjunction with outstanding service and commitment to each customer, and we are local in the US and Canada

Their Know-How enables them to offer many unique custom equipment solutions for fast and efficient manufacturing and extraordinarily short set up times.

Features:

- Pre-melter for 5-gallon (20-kilogram) pails, suitable for PUR adhesive

- The independent control system of the external pre-melter can be adapted to different laminating machines

- Melting capacity maximum 48 kilograms per hour

- 5-inch Touch screen display.

FUX 83-CLM-327 PLUS 2022 edition

FUX Maschinenbau & Kunststofftechnik GmbH - the leading manufacturer of profile wrapping, lamination and profile bending equipment - is showing the 2022 edition of the 83-CLM-327 Plus at GlassBuild.

The 83-CLM-327 model is based on the bestselling profile line 83-PLM-327 from FUX, but in a more compact version, as a very attractive opportunity especially for lamination startups and smaller runs. This line is equipped with a 4.4-pound adhesive topmelter that can easily be changed within minutes to an external 5-gallon adhesive premelter.

Standard Features:

- One side-based drive train with full accessibility on the operator side

- Patented anti-scratch, non-stick and low maintenance slot nozzle from FUX

- Precision primer application through centralized controlled primer pumps

- Central touch screen panel for the control of the line

- Two laminate unwinding reels

- Protective film applicator

Upgraded Features:

- Integrated automatic on spot humidifier system

- Automatic foil positioning system

- Laminate preheating system

- Remote access maintenance modem

- 4 primer pumps

With a company history of more than 475 years, FUX engineers reliable state-of-the art machinery and develops process solutions in conjunction with outstanding service and commitment to each customer, and we are local in the US and Canada

Their Know-How enables them to offer many unique custom equipment solutions for fast and efficient manufacturing as well as extraordinarily short set up times.

Vinyl Bending Equipment

Producing specialty windows is something of an ‘art’ and can prove to be a very profitable part of your business. Don’t take a gamble on your equipment supplier!

- Witte has manufactured vinyl bending equipment for over 35 years

- Known for quality crafted equipment and bending forms.

- Support and expertise are always available to our customers, even years after purchasing equipment.

When it comes to investing in bending equipment the success of your productivity depends on the knowledge and expertise of Witte North America.

Visit us at Glass Build 2022 booth #8011 to find out how Witte can transform your specialty department.

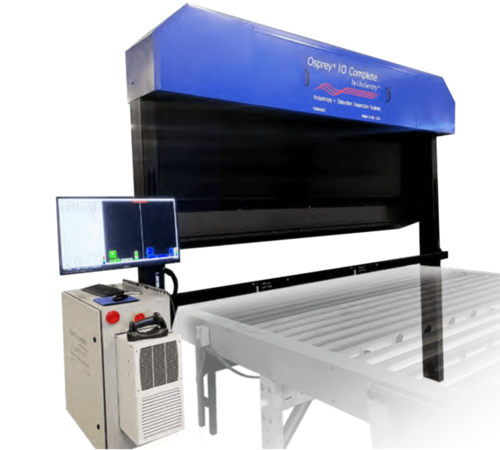

Osprey 10 Advance Inspection System

LiteSentry’s revolutionary Osprey® 10 advance inspection systems include the only high-performing systems that meet and exceed the growing requirements of leading architects and glass suppliers, including mandated distortion and anisotropy measurements.

LineScanner

The LineScanner is the solution for all quality inspections of transparent flat glass products such as single sheets, insulating glass, automotive glass, processed glass, polycarbonate or film. LineScanner inspects your products with extreme precision for all defects in quality and dimension. Its flexibility as well as its simple operation and installation allow it to be put into operation quickly and easily with minimum space requirements.

LaserBird smart

The standard becomes added value

Be it bird protection glass, antibacterial panes, heated glass panels or an RF-transparent IG unit: HEGLA boraident wants to explain how easily a standard product can become a commodity with added value. “With a range of samples, we want to give the impression of how flexibly glass can be finished by removing or transforming the functional layer, or via non-destructive printing with our Laserbird,” explained Dr. Thomas Rainer, the Head of Development at HEGLA boraident. In addition to the option of creating functional glass without tooling time or an additional service provider, Thomas Rainer sees the “single piece” option as a major advantage: “Via the user-friendly GUI or connection to the ERP, each individual pane can be coated with various finishing treatments without any waited time.”

HEGLA Taifin Tempering Furnaces

Greater efficiency and automation for tempering furnaces

“Tempered glass, as perfect as glass can be” is what HEGLA-TaiFin aspires to achieve. The company is known for convection technology and closely controllable heating zones with qualities much higher than the industry standard. “We have one of the best tempering furnaces on the market and at GlassBuild, we now want to show what is possible when strong partners work together,” said Teemu Kolka, Manager of HEGLA TaiFin. The optimal bedload is determined with bed optimization from HEGLA-HANIC. For maximum automation, the glass can be put together with automated batch creation from HEGLA – no operator required. Through “de-batching,” the batch can be separated again. Optional quality scanners monitor quality and, in conjunction with the intelligent optimization of HEGLA New Technology, they adjust the furnace recipes if necessary. Thanks to this holistic view, using such a system increases total throughput significantly and saves a great deal of energy.

Utensile diamantato

Diamant manufactures diamond wheels customized for every processing requirement and application (furniture, architecture, domestic appliances) always guaranteeing the maximum result. It is possible to customize profles, mixtures and grains, guaranteeing a faster, more qualitative and more competitive glass processing. Thanks to constant R&D, Diamant today presents a specific range of cup wheels for laminated glass processing.

La Diamant realizza mole diamantate 'customizzate' per ogni esigenza di lavorazione, garantendo sempre il massimo risultato. E' quindi possibile personalizzare profili, impasti e grane garantendo una lavorazione del vetro più veloce, qualitativa e competitiva. Diamant oggi presenta una gamma specifica di mole per la lavorazione di molteplici tipologie di vetri.