Infor CPQ (Configure Price Quote)

Infor CPQ has over 20 years of experience in fenestration and is widely regarded by the analyst community as the best solution for manufacturers, with its ability to handle simple and very complex pricing and configuration. Infor CPQ brings our customers’ products to life through an interactive, dynamic, real-time, 3D engagement experience for selection visualization. This supports brand engagement during the research process and captures the anonymous users’ interest long before engagement with sales, driving inclusion in unknown opportunities.

From within a corporate website, quoting experience, CRM, and / or ERP, Infor CPQ’s rich, compelling, visual platform allows any user – an anonymous prospect, customer, salesperson, distributor, dealer – to research, select, specify, quote, and order their simple and complex products faster. This wins more business, differentiates brand, and avoids wasted time, duplicate activities, costly errors, and friction within the processes.

Infor CPQ’s unique and deep manufacturing integration is standard with Infor (and non-Infor) ERPs, using the exact same technology to generate accurate bills, routings, shop orders, CAD drawings, and model assemblies. This decreases costs, by leveraging a single technology platform from research to delivery. Infor CPQ’s enterprise solution delivers the lowest total cost of ownership in the fenestration industry.

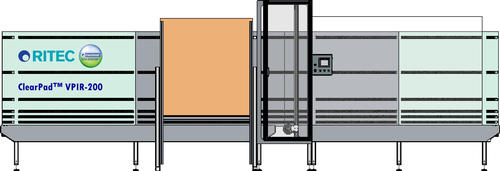

ClearPad VPIR-200

Ritec ClearShield® Durable ‘Non-Stick’ Easy-Clean Glass Surface Protection

NEW! ClearPadTM VPIR-200 vertical pad Ritec ClearShield® application with infrared-reflective (IR) pre-heating

PROCESS FASTER • LESS LABOR • INCREASE PROFIT

The most efficient way of pad-applying Ritec ClearShield®

- Reduces handling, labor costs and application training

- Faster production with IR pre-heating for instant curing

- Increased and consistent coverage rate

- Management and control software to maximize product usage and avoid waste

- Small footprint.

PDS ProFilm System

PDS PROFILM System allows fabricators to protect their glass immediately through a high-speed inline applicator that is capable of maintaining insulating glass (IG) line speeds.

Why People Choose Protective Film

- Product cleanliness from factory to finish

- Reduces end of job cleaning time and costs (weld splatter, stucco, paint, mud, concrete, etc.)

- Reduces potential for damage during manufacturing

- Minimizes scratches during installation

- Reduces product returns

- Replaces interleaving between IG units

- Serves as low-cost insurance

- PROVIDES A POSITIVE EXPERIENCE FOR THE CUSTOMER!

System features:

- Auto measuring technology that simplifies the life of the operator

- Fast – ability to film more than 1,500 operating sized units per shift

- No film trimming required. Operators just load and unload.

- Module Sizes: 60 by 60 inches; 60 by 90 inches; 96 by 120 inches or made-to-order

- Accepts varying widths of film (8 to 16 inch)

- Adjustable edge cutbacks (minimum 1⁄2 inch from edge).

PUNCH TOOL FOR CURTAIN WALLS AND STOREFRONTS

Pneumatic Punch Tools for Curtain Walls / Facade Systems / Commercial Systems / Storefronts / Commercial Entrances / Window Wall / ShopFronts.

Shoham’s punch presses are designed to save valuable processing time by providing a fast and efficient production line. Unlike other machinery, pneumatic punching machines can eliminate the slow and tedious process and deliver in just a few simple stages.

Our tools can punch multiple applications:

- Pressure Plates

- Covers / Caps

- Head / Sill Anchor

- Shear Block / Clip

- Holes in Mullions (including countersinks)

- Notch Heads and Sills to Clear Anchor Clips

- Water drainage and weep holes

- Mullion holes for shear blocks

- Holes for screw spline application

- Frame fabrication – Sill

- Center glaze, flush fronts, open back mullions, pressure bar / face cap dies.

Advantages:

- Faster than drilling and routing, labor time is spared on each and every punch

- Fast and easy assembly

- Operator friendly – only one operator is required

- Dimensions / setup can be changed upon customer’s request

- Quick lead & delivery times.