Glass Rectangle Slitting (Strip Cutting)

Appliance, as well as some other manufacturers, need to process small parts for things such as refrigerator shelves. It is more costly and difficult to handle if the raw glass comes from the float line in small pieces. Therefore a slitting line is one solution, whereby the glass can be shipped in larger blanks, and slit, or cut down into the smaller pieces required. Slitting is the process of using multiple cutting heads to score a sheet in a straight line. This slitting can happen with the glass moving past fixed cutting heads, or by placing the cutting heads on a bridge with the glass fixed in position. In the case of the example shown, the block is automatically loaded by our overhead loader, and the block is automatically positioned so that the slit pieces are of a nominal size tolerance. The glass is then transferred under the slitting bridge which has five slitting heads. These heads are automatically set up to size by the program based on the size of the block and the size of the parts desired. The glass is then transferred, the scores are snapped, and the individual parts are fed into a Glassline double edger, which is the only edger fast enough to handle parts at this speed. Other slitting configurations can be proposed depending on your needs.

Proliner Glass Package

Accurate digital measuring for Flat or Curved glass made easy!

Glass fabricators using the Proliner have improved their overall production process by significantly reducing the time required for measuring and creating digital templates for glass constructions. Due to the Proliner’s accuracy, expensive waste products caused by inaccurate measurements now belong to the past.

There is a clear distinction in the requirements for creating digital templates for flat glass constructions and (double) curved glass constructions. We offer special solutions for both. Operators can easily create, check and change digital measurements in the factory or on the job site and use the rapidly created DXF files for further processing or as direct input for machinery.

Proliner Glass Templator package (Architectural and Bent Glass)

Since there is a clear distinction in the requirements for creating digital templates for architectural glass and (double) curved glass constructions, we developed complete glass package solutions for both.

The Proliner Architectural Glass package is a complete digital templating solution that enables architectural glass fabricators to measure, check, edit and export digital templates of balustrades, backsplashes, worktops, windows, physical templates, and other flat glass shapes on-site as well as in the factory.

The Proliner Bent Glass package is a complete digital templating solution for measuring and creating digital templates of bent glass constructions. The Bent Glass software enables glass manufacturers to model, flatten, frame and compare 3D glass shapes.

Prodim will analyze your business activities and particular requirements and use our many years of experience in the glass industry to create the best total package for improving your templating and business processes now and in the future.

TRUE

TRUE is a web-based Enterprise Resource Planning (ERP) software solution designed for glaziers. It includes tools for managing leads, generating proposals, timekeeping, scheduling, work orders, procurement, inventory control, job costing, invoicing and accounting, while also being fully integrable with any version of QuickBooks. Whether you're a residential, field service or commercial contractor, let TRUE help you take your business to the next level.

Smart-Toolbox

Smart-Toolbox is a job management system built for the glass industry. Remove your bottlenecks and make it easy for anyone on your team to quote, schedule, order and invoice. Our glass job statuses and dashboard will allow you to catch mistakes before they become problems. And our interactive online quotes will allow your customers to visualize their glass or shower, accept the quote and even pay online.

Stop chasing paper, hunting for folders and interrupting your teammates every time a customer calls. Work smarter not harder with Smart-Toolbox.

Extra power for shower specialists

Smart-Toolbox can include our 3D Shower Designer capable of automatic deductions. It integrates with the free Smart-Glazier App, giving you the ultimate shower measurement and design package.

What do our customers think?

“I really couldn’t imagine running my business without Smart-Toolbox” Glass Castle

Why choose Smart-Toolbox?

We've been building glass software exclusively for glaziers, glass fabricators and hardware suppliers for over 20 years. We work very closely with our customers to improve our tools and make them the best in the industry.

www.smart-builder.com | 628-226-2017

Smart-Glass

Smart-Glass is the brand-new, browser-based, glass design & ordering platform that works on your PC, Mac, tablet and even your mobile phone!

Online order entry portal for fabricators

If you're sick of receiving customers’ orders on napkins, scraps of paper or cardboard, then come & talk to us. Find out how you can give your customers a dedicated login to draw, price and order their glass from their phone or tablet, anywhere, anytime. Built-in warnings alert them to mistakes so they can place orders with confidence. Your team will receive accurate, fabrication-ready glass orders that can be imported into a range of fabrication software systems, such as A+W, Optima, Lisec & Glasstrax.

Showers Online Integration

We also are proud to offer the ability to connect ANY Showers Online account to Smart-Glass. This will eliminate the need for double-entry and remove the chance of human data entry errors. If you’re fabricating shower glass – you need to see this.

We've been building glass software exclusively for glaziers, glass fabricators and hardware suppliers for over 20 years. We work very closely with our customers to improve our tools and make them the best in the industry.

www.smart-builder.com | 628-226-2017

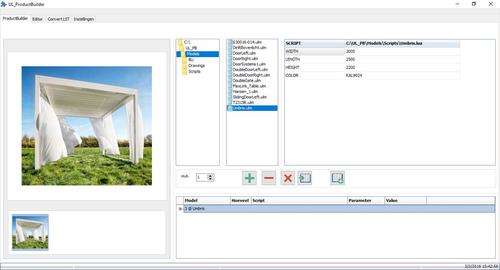

Product Builder

The Product Builder is a powerful design solution for the production of parametric constructions with extruded profiles like fire doors, sun protection, balustrades, conservatories. It is a solution for manufacturers that do not use calculation or drawing software, allowing constructions with profiles to be made as parametric models based on scripts. The models allow the manufacturer to generate machine data, barcode labels, DXF drawings, numerous reports and, if necessary, give feedback to the manufacturers ERP system. From Product Builder the production lists are sent straight to the machine work floor enabling focus on the following tasks.

Using extremely powerful scripting models and algorithms, this software provides endless possibilities when it comes to executing design ideas and turning them into drawings and production lists.

Industries that produce large numbers of similar but customized products can benefit from using our Product Builder, though the ease of implementation and execution is a great tool for manufacturers of any size.

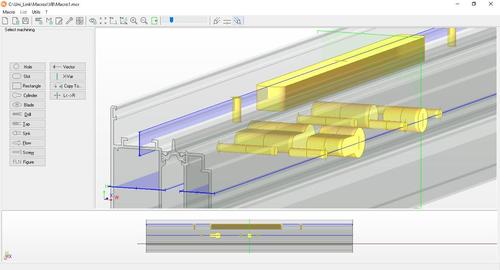

UNILINK Platform

UNILINK is an independent automation platform for production on CNC machines in the industry for aluminum, steel and PVC profiles used for doors and windows or any other profile industry.

Our platform includes a machine independent, vector based, 3D macro programming interface designed to be user-friendly, fast and capable of managing huge macro libraries.

There is a list editor to view and edit your production data. The UNILINK platform can import data from any construction software and export to any brand CNC profile milling and cutting machine.

The software contains functionalities like tool assignment, anti-collision and bar optimization. The user creates all complex production lists with a maximum of automation, determining from the office if a machine is capable of running a job without collisions and receiving a visual report of the tool assignment before starting the machine. The machine operator only handles the profiles, allowing the machine to work continuously.

Additionally, we offer a powerful optimization module that ensures a minimal use of material. Any excess can be easily integrated in the following optimization. The same goes for damaged profiles; for example, damaged spots on bars can be detected and cut out by the optimizer.

UNILINK provides partners a comprehensive toolbox for managing tasks within their machinery, even multiple brands of machines, different construction software or different companies. We will create the right solution and grow together as loyal partners in the art of automation.

A+W Smart Companion for Fenestration Manufacturing

Barcode scanners are an indispensable tool for window and door manufacturers. Smartphones and smart devices are playing an increasingly important role, when equipped with the A+W Smart Companion App for the A+W Cantor software solution. Smartphone cameras allow barcodes to be scanned directly and to display additional information. The app supports materials management and requests, dynamic forms (the customer customizes their own scenarios in Production), and increases digitalization. The intuitive user interface requires no training, which helps save time and money.

A+W Smart Companion for A+W Cantor is currently available for Production and Stock.

In the dispatch area of production, the app can book finished elements and accessories onto racks while also assigning them to an area. This allows several elements to be scanned simultaneously in so-called continuous mode (camera mode).

As a mobile info terminal (read mode), the app provides support by displaying, for example, the production status of individual order items. This provides information at all times during production.

The stock area allows goods receipt, material transfer postings, and inventory postings to be completely processed via the app. For example, an overview of all counted items can be displayed and found directly in A+W Cantor.

A+W iShape II

Our second-generation A+W iShape II allows for quicker fabrication, greater functionality, and increased user-friendliness. To start, place A+W’s reference L-angles inside the template’s perimeter. Utilizing the app’s camera feature, the user photographs the template against a contrasting background. The data, including perimeter and radii, are calculated in the cloud with the special L-angles serving as the scaling tool of the template. Users then receive a ‘confidence factor’ regarding the template’s quality and, if acceptable, the user can email the file to A+W CAD Designer, where imperfections (folds, unintended crooked cuts, etc.) can be massaged out with the line tool. Now the shaping/nesting file (dxf) is ready for cutting. If templates are a significant part of your business or even a significant spend of your time, A+W iShape is the solution for you.