Company Profile

Inspection + measurement systems for flat glass quality control. LiteSentry’s systems are 100% on-line, non-contact, precision metrology tools for value-added glass fabrication

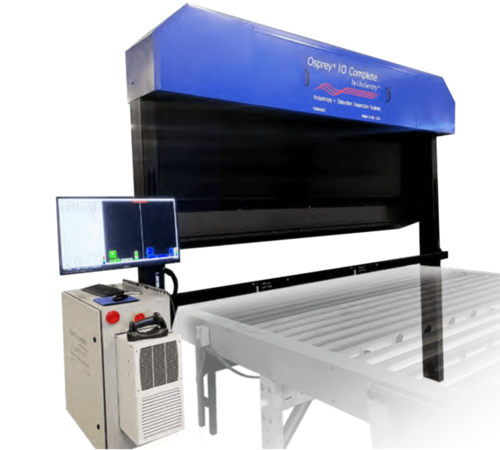

- Osprey® 10 Complete Anisotropy, Overall Bow Recognition + Distortion - Measure anisotropy, distortion in mD (milliDiopters) and PV (Peak-to-Valley inch + mm)

- NEW TO OSPREY 10 - Overall Bow Recognition - OBR - OBR is a LiteSentry proprietary quality test that recognizes bowed or bi-stable pieces of glass in real-time and displays results alongside other Osprey data before pieces are removed from the furnace unload table.

- Osprey 10 Distortion + Flatness - Only system to measure true distortion in mD & PV

- Owl 4 Furnace Optimization System: Recipe Selection / Load Validator / Missing Part Notifier - Process Control for Batch Tempering Furnace. Measures thickness, lowE coating, confirms load size + geometry. Data sent to furnace for recipe + tempering optimization

- TemperQC - Integrates LiteSentry + 3rd party equipment into a complete Tempering Quality Control system

- Hawk 4 Scratch + Defect Inspection

- Thickness & Coating Sensor - Measures thickness, coating type, 4th surface LowE.

Product Categories

Products & Information

Osprey 10 Advance Inspection System

LiteSentry’s revolutionary Osprey® 10 advance inspection systems include the only high-performing systems that meet and exceed the growing requirements of leading architects and glass suppliers, including mandated distortion and anisotropy measurements.

LineScanner

The LineScanner is the solution for all quality inspections of transparent flat glass products such as single sheets, insulating glass, automotive glass, processed glass, polycarbonate or film. LineScanner inspects your products with extreme precision for all defects in quality and dimension. Its flexibility as well as its simple operation and installation allow it to be put into operation quickly and easily with minimum space requirements.